Crossfire Specialist Contracts are a leading provider in structural fire protection. We combine the latest technology with years of experience and a dedication to best practice. Our teams can adopt a diverse range of structural fire protection methods to ensure our client receives the best possible solution to meet their requirements as well as offering full compliance with the local Building Regulations.

Crossfire are third party accredited in applying intumescent coatings, cementitious sprays as well as board protection, combining this with our technical knowledge within the Structural Fire Protection provides our clients with peace of mind.

Structural fire protection is often vital for reinforcing steel structures within any building. By adding a protective layer to structural steel, the protective layer extends the length of time a building remain structurally stable within a fire scenario. Structural fire protection not only reduces the damage to a buildings structure in the event of a fire, but also increases the chances of the occupants within the building evacuating safely.

Crossfire specialises in the application if intumescent coatings for steel structures. With our experience and technical knowledge, we can rapidly protect structural elements without compromising their basic functionalities or aesthetic finishes. With our adaptable approach to each project, Crossfire is capable of applying intumescent coatings both onsite and offsite, offering our clients an unrivalled service.

Crossfire innovatively use modern technology onsite to record the Dry Film Thickness (DFT) of the applied intumescent coatings, therefore creating reliability and traceability of each painted member within our clients building.

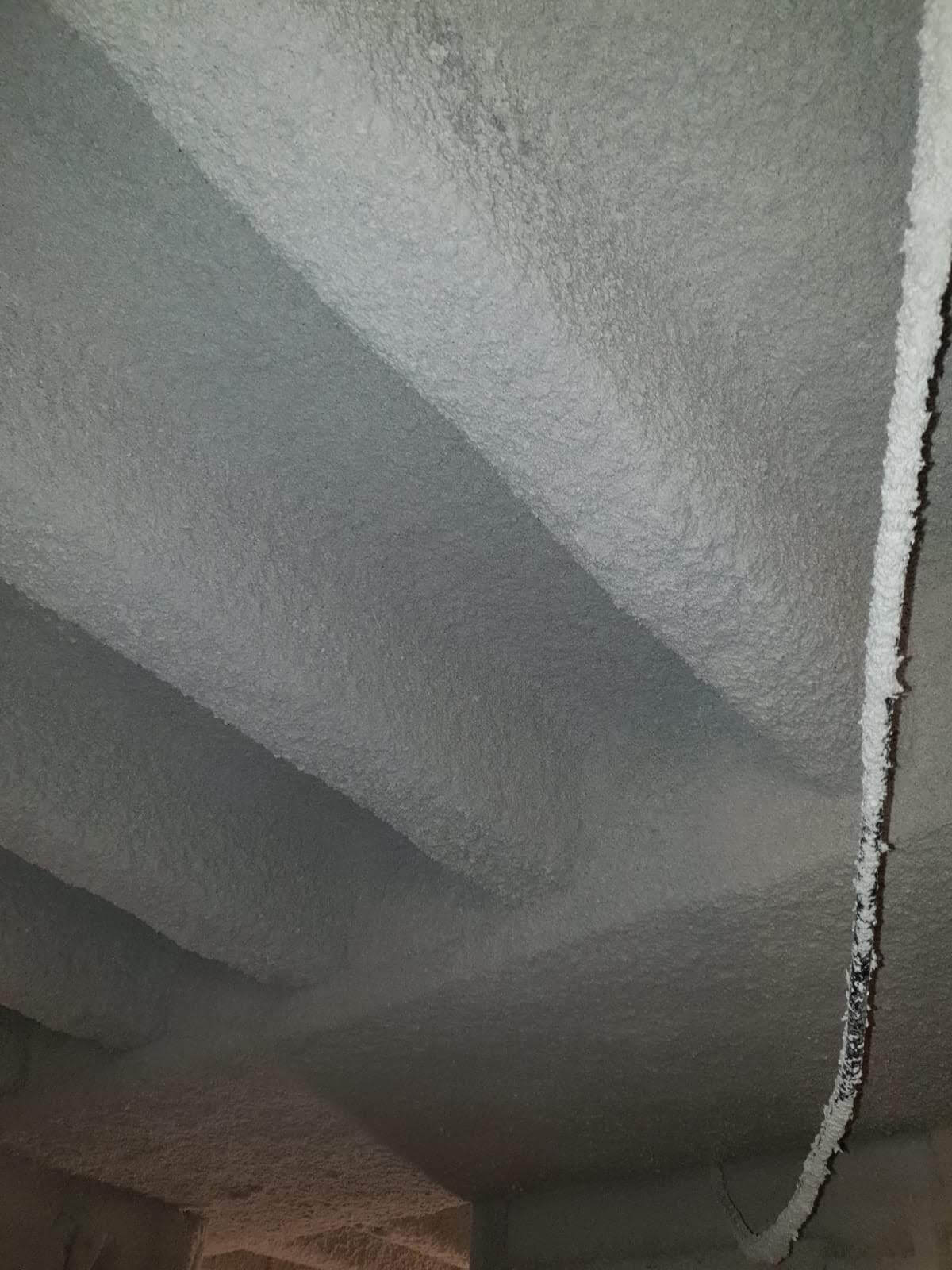

Crossfire hold and maintain FIRAS third party accreditation for Cementitious Coatings, therefore resulting in our work being completed to the highest of trade standards and best guidance.

Crossfire have heavily invested in cementitious sprays, and have the most advanced equipment to apply our coatings.

Cementitious protection is a fast and cost efficient method of providing up to 240 minutes fire protection to structural steelwork. Regarded as a non-decorative cementitious mortar based solution for use in the commercial and industrial sectors; these materials can be used in environments prone to impact and abrasion. Materials can be applied quickly in one spray coat to achieve 2 hours fire protection; this can reduce on site labour and application time costs compared with other multiple coat disciplines.

During our work and on completion of spray applications we are able to produce records of who applied, which area the work was carried out in, what specified system was used to protect the area and when the work was done. Each application area can be physically identified through this electronic data recording process with detailed drawings and photographic support available. You may also want to consider utilising our company’s contact information label that can be fitted to each section or area on site.

Encasement fire protection boards and lining systems are efficient methods for providing up to 240 minutes fire protection to structural steelwork with protection of construction linings such as walls and soffits with mechanical service system protection also available.

Based on the substrate type and levels of protection required when installed to the correct board thickness and mechanically fixed to specification, encasement materials can provide a viable cost effective and low maintenance solution.

Board and lining systems can provide concise cut to profile and aesthetically pleasing designs that are durable and moisture resistant whilst offering high levels of acoustic performance with fire protection. Surfaces can lend themselves well to final decoration to meet your projects overall colour scheme requirements as well as complying with the local Building Regulations Requirements.

Crossfire offers our clients on a range of versatile encasement specification solutions to ensure structural and service protection are provided and maintained at site in compliance with the local Building Regulations.

During our work and on completion of encasement installations Crossfire produce records of who installed, which area the work was carried out in, what specified system was used to protect the area and when the work was done. Each installation can be physically identified through this electronic data recording process with detailed drawings and photographic support available. You may also want to consider utilising our company’s contact information label that can be fitted to each section or area on site.

This scheme allows you to deal with future work effecting installed systems or maintenance of existing encasements, using the contact details provided on the company label.